Test & Measurement

Multimeter

Todo

Discuss the various types (handheld and bench), what to look for in shopping, and their purpose.

Oscilloscope

Todo

Discuss the various types, what to look for in shopping, and their purpose.

Signal Generator

Todo

Discuss the various types, what to look for in shopping, and their purpose.

Bench Power Supplies

Todo

Discuss the various types, what to look for in shopping, and their purpose.

Microscope

Todo

Discuss the various types, what to look for in shopping, and their purpose.

Physical Measurement

Choose Your Own Path

You may have to make a choice in your life as a maker. Do you go down the path of metric, or do you stay in the darkness and continue to measure things with some of the most absurd units imaginable. Alas, you can't completely eliminate the customary system, but you can choose not to propagate more of it. But that's just my opinion, man.

Rulers

I know it sounds super obvious, but I very highly recommend you own a set of decent quality stainless steel rulers. McMaster-Carr has a great selection, and I would recommend at least having them in 150mm (6") and 300mm (12"), but depending on what you're working on, it may be helpful to keep a larger one around. These will all be marked in at least 1mm and 1/16th (but preferably 1/32nd) of an inch. And yes, in spite of my shot at customary measures, you should get one with both, unless you're lucky enough to live somewhere where metric is exclusively what you use. Even then, there are certain industries (PCB manufacturing) where everything is talked about in thou (thousandths of an inch).

Tape Measure

Separate from a ruler, sometimes you need to measure something longer than 300mm. At that point, a tape measure is the thing you want. I'm a big fan of the Stanley tape measures, either the PowerLock or the FatMax models. Both can reach quite far without support, are accurate, well made, and relatively cheap. Typically, I would recommend a 16 or 25 ft model (yes, I know). Stanley makes a nice PowerLock that is marked in metric and customary, the 33-158.

Calipers

Calipers are perhaps the single most indispensible tool you can have for measuring things. They allow you to very accurately determine the size (and therefore exact shape) of something you're looking to model, or model against. They allow you to verify prints. They allow you to check parts to ensure they're the dimensions you thought they were. They come in a dizzying array of styles as well as read-out mechanisms (vernier, dial, and digital). Quite honestly, I just recommend getting the digital models unless you know you need or want the others.

As for manufacturer, well, there's always Mitutoyo, who is, perhaps, at the very top of the metrology game here. Or Starrett. If you're rolling in money, buy one. They're beautifully made and supremely accurate. You can go spend $700.00 on a single pair of calipers on a single 300mm pair. But what, realistically, should you get? I have been using a 150mm (6") model from Clockwise, the DCLR-0605. It is likely available easily at your favorite mega retailer, and costs around $25.00 . There are 200mm and 300mm models as well, but I don't feel like I typically need that level of exacting dimension across that wide a space.

See elsewhere for how to use them.

Feeler Gauge

Mechanical creations are built up from a series of parts. Those parts have to be put together, which is termed "mating". For that to work correctly, they have to be designed within a specific fit and tolerance. Too tight and things won't go together, but too loose and they'll rattle or fall apart. To check the gaps and clearances are what you expect, you can use a feeler gauge.

A feeler gauge is, basically, just a series of plates of metal (typically stainless or carbon steel) that are precision machined to specific thicknesses. These can also be called a straight blade gauge. This is what's in the photo. They come in various sizes, and obviously come in either metric or imperial/customary. The ones pictured were inexpensive (< $10 USD) and range from 0.02-1.0mm, which is more than enough for my purposes. I suppose you could be super fancy and buy a set from Mitutoyo for 5-10x as much. What I do just isn't that exacting.

To use a feeler gauge, I would recommend you watch this video, which, in spite of using customary units, is an excellent introduction to how to use a feeler gauge, and more importantly how to actually understand the "feel" it's referring to.

Thread Gauge

We use a lot of screws (and bolts) when making things. It's one of the best, and most durable, ways of putting things together. Sometimes, though, when you're working on a project, you find yourself with a screw or screw hole that you're just not sure about. Is it the right size? What size is it?

This is where a thread gauge comes in. These are, like feeler gauges, made from either carbon or stainless steel, and are ground to have exact cuts for the threads. You simply can go through them, until, as shown in the photo, they match up perfectly. In this case to a stainless steel 1/4-20x1" socket head cap screw.

While there are very expensive ones available, I feel like a generic inexpensive one with both customary and metric threads on it would be helpful occasionally.

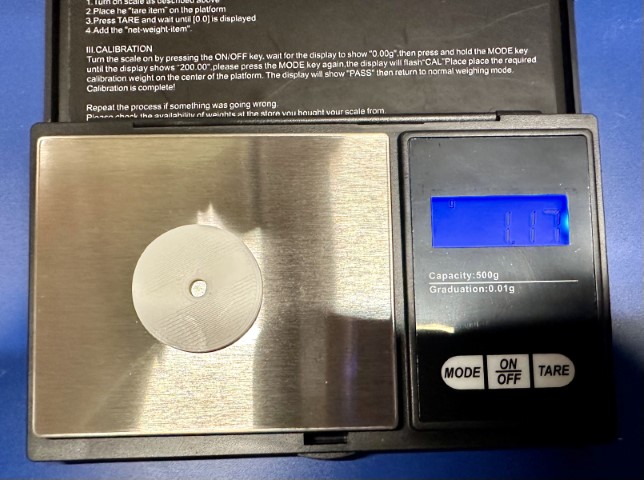

Jeweler's Scale

Working with electronics, and most maker hobbies, you're not typically dealing with very heavy things, but sometimes it's important to know how much something weights. The best thing I've found is an inexpensive jeweler's scale. These are typically accurate below 0.1g and can display weights in grams (correct), ounces (what is this even?), and often a bunch of jeweler specific things, like grains and carets.

Comments or Questions?

If you have any comments, questions, or topics you'd like to see covered, please feel free to either reach out to me on Mastodon (link below) or open an issue on Github.