Soldering

See this page for information about soldering irons and equipment. This is primarily concerned with the consumables.

High Temperature and Fire Hazard

A normal soldering iron can quite easily reach nearly 500C (932F), and while typical soldering happens closer to 350C (662F), that temperature is high enough to cause instant ignition for many flammable materials. In addition, that temperature will cause immediate burns if touched.

DO NOT ever leave a soldering iron or hot air station unattended, even for a few minutes. If you are not currently using the soldering iron, make sure it is turned off, and you should consider investing in a timer switch to ensure it is turned off no matter what.

Solder and Flux

Solder is a metal alloy used to create strong permanent bonds such as attaching components to a PCB, or joining wires together. It comes in two different types, lead and lead free, and also can be had in a wide variety of diameters (typically 0.015" to 0.125"). Inside any solder intended for electronics is the flux, a material used to clean, strengthen, and improve its mechanical properties.

Flux does its job by removing impurities from the surface of the joint and preventing them from interfering with the bond between it and the solder. Flux comes in liquid, paste, or powder form, and can be used before and during the soldering process.

There are three main types of flux in common use:

- Rosin

- Made from pine tree sap which is dissolved in a solvent (usually isopropyl alcohol). It is slightly acidic, which helps activate it.

- No-Clean Flux

- This is a rosin-style flux with minimal activation (mostly acidity). This means you don't have to remove it after assembly. Unfortunately, it's also less effective at preparing the board for soldering. Also, you should clean it anyway, as it can leave a sticky residue.

- Water-Soluble Flux

- This is based on a totally synthetic resin base. It is still quite corrosive (even more so than rosin in some ways), which does lead to a well-prepared surface, but it also means it must be cleaned as well. It may generate less harmful fumes due to its use of water as a solvent.

Composition of Solder (Lead/Lead-Free)

There are two major categories of solder: lead and lead-free. Before we freak out about the lead, the lead is not vaporized, and is not part of the smoke you see when soldering.

Lead-Based Solder

Lead based solder is the traditional formulation, and has a low melting point (180C) and good flow and wetting properties. There are two primary formulations in use:

- 60Sn/40Pb

- 63Sn/37Pb

The main difference between the two is in how they melt and solidify. 60/40 solder becomes plastic around 183C and fully melts at 188C. The range between (183-188C) is considered the plastic region. Because it can spend more time in this plastic region, it has a higher tendency of forming a cold solder joint.

What is a cold solder joint?

A cold solder joint is one where the joint has not been properly heated and did not melt completely. It can happen for a number of reasons: using too little heat, not applying heat evenly, or not applying heat for long enough. Cold solder joints are weaker than proper ones and can cause electrical problems.

You can tell a solder joint is cold by looking at it under a magnifying glass. A cold solder joint will look dull or grainy, while a well-soldered one will be shiny and smooth. You can also try to move the component. If the joint is weak, the component will move slightly.

63/37 solder, on the other hand, is a eutectic. Unlike 60/40 solder, 63/37 melts and becomes solid at a singe temperature (183C), eliminating its plastic region and reducing the possibility of cold solder joints. One minor bonus is that 63/37 solder solidifies into a slightly shinier and smoother surface. It's also slightly more expensive.

Which should you use? Either. Just buy a decent brand.

Lead-Free Solder

TODO

Need to write about this, but right now I don't feel like I know the topic well enough.

Wire v Paste

There are two main types of solder that you'll see as a hobbyist: solder wire and solder paste. Solder wire is primarily used for wires, through-hole components, and larger SMD devices (although you can do miracles with smaller with some techniques). Solder paste's sole dominion is surface-mount technology. If you're just starting out, start with wire.

Buying Solder

So, now that you know a bit about what solder is, how do you go about buying it. There's a few things you will need to think about. First, make the choice between leaded and lead-free. My recommendation would be for leaded solder as it is much easier to solder as a beginner. Second, choose a formulation (either is fine). I'd also stick with rosin flux cores. Then you'll need to pick a solder manufacturer. These are the solder brands that I would stick to:

- Chip Quick

- Kester

- MG Chemicals

Lastly, you'll need to pick a solder diameter. My two preferences are for something around 0.020" (0.51mm) and 0.062" (1.57mm). These give you options for both fine work and more bulk work (like tinning large wires). Personally, the main solder I use Kester 44 in those two sizes. I also happen to keep them both stored on a Hakko 611 dual-spool holder. It's inexpensive, but it keeps things tidy.

Storing Solder

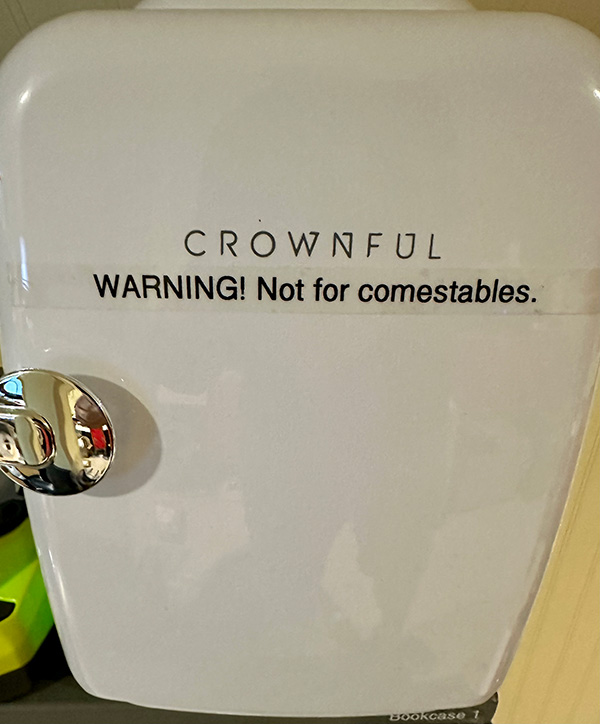

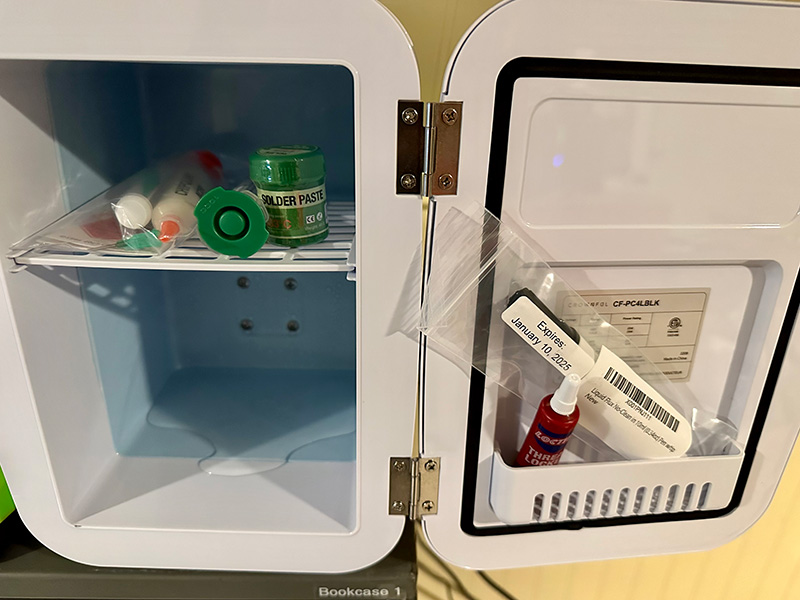

Solder does/can expire, although solder wire will last much much longer than paste, and in non-production uses, it's probably going to be fine forever. Solder paste, however, needs to be stored in a controlled environment. Adafruit has more on this, but I store mine in a cheap little Peltier-cooled fridge that was super cheap (it's also not super efficient, but it's tiny so it doesn't matter):

Comments or Questions?

If you have any comments, questions, or topics you'd like to see covered, please feel free to either reach out to me on Mastodon (link below) or open an issue on Github.